Here’s a scenario. You’re in a warehouse facility and you want to determine how many lights are best for your space. How do you go about choosing the right warehouse lights? This can be tricky because there’s so much to consider.

A lot of people wonder what the best number of warehouse lights is for their facility. This is a question that needs to be asked because too many people underestimate the number of lights they will need. That is why it is important to know the number of warehouse lights needed before you purchase the lights. The number of warehouse lights needed is dependent on the size of the facility and the amount of warehouse space you have. This blog will help you find the number of warehouse lights you need for your facility.

Table of Contents

What Are Warehouse Lights?

Warehouse lights are the most common type of commercial lighting. They are typically used in large warehouses and manufacturing facilities, although they can be found in other types of buildings as well.

Warehouse lights are designed to illuminate large areas with a broad, even light source. They are usually mounted high up on walls or ceilings so that they don’t interfere with workers’ movements. Warehouse lights are generally either fixed or adjustable, with some having the option to be both.

Fixed warehouse lights provide a fixed amount of lumens (the measure of light output) in a specific area, while adjustable warehouse lights can be tilted and aimed to focus their light output on specific areas. Some warehouse lights with sensors have automated features that allow them to turn on automatically when motion is detected and turn off after leaving for a period of time.

Warehouse lighting can be found in a variety of different ways:

High bay warehouse lights – These types of lights are used in high ceilings, where there are no obstructions from the floor to the ceiling. They are mounted directly on the ceiling and produce a wide-angle beam that covers most of the area below it.

Low bay warehouse lights – These types of lights are ideal for warehouses with low ceilings and many obstructions from the floor to the ceiling. They are mounted directly on the ceiling like high bay warehouse lights, but they are with much less power that illuminates only a small part of their surroundings.

In addition to their mounting type, warehouse lights can also be divided into two categories: traditional or LED (light-emitting diode). Traditional lights, such as high-pressure sodium lamps, metal halide light,s and fluorescent bulbs have been around for decades now and they’re still popular because they’re easy to find and affordable. However, LED technology has improved significantly over the last few years and they’re becoming more popular due to their low energy consumption compared to traditional bulbs which use quite a bit of electricity when compared with LEDs which only require a fraction of electricity.

How many warehouse lights do you need?

This is a question that you must ask yourself when planning your warehouse lighting.

When lighting a warehouse, the amount of light needed depends on the size and use of the area. To calculate how many lights are needed, you should first determine how many footcandles you want to achieve. Then you can determine how many lumens your fixtures will need to produce that level of brightness. After spacing out the lights evenly, consider whether or not you’ll need dimming capabilities or if you’ll need to adjust the beam angles of each fixture individually.

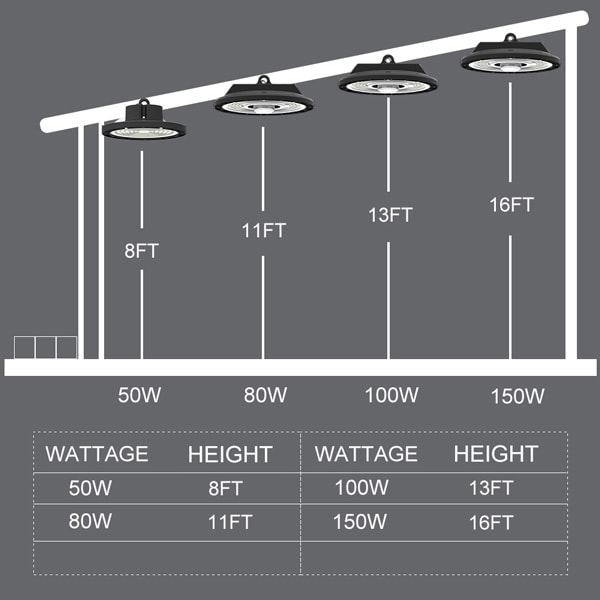

When planning your warehouse lighting system, consider the height of your building and follow the recommended guidelines for spacing between fixtures.

To determine the number of ufo lights required for a warehouse lighting installation, you must first measure the area to be lit and the height at which the installation will be performed. This allows you to plan your layout efficiently. Next, you should review existing light sources (if any) in order to determine if they have proper spacing. If this is the case, then using existing fixtures may save you money on installation costs. Finally, you can lay out your grid pattern according to your measurements and desired spacing between fixtures.

For example, if you install lights 15 feet high, approximately 20,000 lumens should be sufficient with about 14 feet between each light. If you install lights 25 feet high, approximately 30,000 lumens should be sufficient with about 20 feet between each light. If you need help determining optimal spacing and height requirements for your warehouse interior, please contact us via email or phone so that we can assist you directly with your quote request.

How much coverage area is one fixture?

The amount of space covered by a lighting fixture can be determined by the mounting height and lumen output of the fixture. Depending on the size of the area, you may need to increase or decrease the number of lumens. For example, if you are installing fixtures in a warehouse storing large items such as cars, you should aim for 10 lumens per square foot; however, if you are installing them in a warehouse storing smaller items such as books, 30 lumens per square foot may be adequate. A simple method for calculating lumen requirements is shown below:

Lumens= lux x (square meters)

Lumens=100 × (200) =20, 000 lumens.

Designing a warehouse lighting layout

One of the first considerations in designing a warehouse lighting layout is determining how the ceiling is constructed. You also need to determine the length and width of the room in addition to other dimensions, such as the height from floor to ceiling. This information will help you calculate how many foot candles (a standard unit of illumination) are needed for adequate lighting in the room.

You should also consider whether you can rearrange the contents of your warehouse to make it more efficient. Different kinds of warehouse lights are suited for different purposes. For example, linear aisle lights are ideal for lighting the aisles between shelves, whereas panel high bays provide brighter light over a broader area. You could also choose LED lights as they are cost-effective, produce warm-free light and last longer than traditional bulbs.

Sometimes warehouse lighting may be difficult to evaluate. The length, width, and height of a room are some of the factors that can make determining an efficient lighting solution difficult. In this case, a photometric study is useful in determining the most cost-effective and efficient lighting plan for the facility. A photometric study uses computer modeling to simulate light output in a given space; it provides information about how bright light fixtures will appear in different parts of a room and whether they will provide enough illumination. Photometric studies are useful both for architects who need to determine a space’s appropriate lighting levels and for lighting designers who need to verify that their designs will meet those levels.

Choosing a proper wattage and lumen

Due to recent technological advances, the traditional measure of light output—watts—is no longer a reliable metric for LED lighting. Instead, lumens are the best way to measure brightness. If you are replacing 250W Metal Halide with LED equivalents, you should use between 80-100W of LED with 11 000- 14, 000 lumens of light output.

If you’re replacing a 400-watt metal halide fixture, consider our 150-watt LED alternative with > 22, 000-lumen models. If you need more light, upgrade to our 200watt LED fixture; if you need less light, consider our 100 watt LED model.

Footcandles And Lux

In the warehouse lighting industry, two units of measurement are commonly used to describe the intensity of light: footcandles and lux.

Footcandles measure how many lumens per square foot are being emitted by a light source. One footcandle is equal to 10.764 lux, which is a unit of measurement that describes how much illuminance exists in a given area.

In general, the more footcandles you have in your warehouse, the better it is for your employees’ productivity. However, you should make sure to use high-quality lights that won’t cause eye strain or fatigue—especially if you have sensitive employees who work long hours in your facility.

Dimming&Tunable CCT

Power usage is a major concern when choosing lighting. You can reduce your lighting costs by using LED lights with dimming or low-wattage capabilities. Dimming makes it possible to change the brightness and color of your lights at any given time, which can be especially useful if you need to adjust the level of illumination in response to changes in seasonal shifts or other environmental factors. Wattage control also helps you save money on energy bills by allowing you to dim your warehouse lights with a simple switch.

In addition, you can also have tunable Kelvin/color temperature in your warehouse LED luminaires. This option allows you to choose varying light colors that fall within different temperature ranges—from warm white (3000K) through neutral white (4000K) to day white (5000K).

Conclusion

Ultimately, you’re going to want to use a combination of these various factors to make your decision. Knowing the right amount of lights to set up in your warehouse is not as simple as it may be. We hope that this post has been helpful. No matter which application you try, keep in mind that installing the proper lighting will certainly improve safety in your building and make it easier for everyone to work. We look forward to hearing about your warehouse lighting solutions! If you need help from us, please don’t hesitate to contact us!