Food Processing Lighting is an increasingly popular choice for food processing plants because of its efficiency and durability. There are many special requirements for luminaires used in these facilities and it is more and more important to select the appropriate LED light Food Processing Lighting for your plant with the rapid development of manufacture.

A food processing plant normally has partitions for raw material receiving, packaging, product inspection, processing, storing, etc. Every part should be equipped with the comfortable and properly bright luminaire. For example, the Food Processing Lighting in the inspection area should be bright enough to help employees check whether the product is broken or damaged by checking its appearance and quality as well as its weight and size. Besides, as employees need to work long hours under artificial lighting conditions, glare from poorly designed fixtures can cause eye fatigue which might lead to mistakes during inspection due to a lack of concentration.

Table of Contents

Importance of Food Processing Lighting

- Food Safety: Food Processing Lighting is crucial for food safety, as it helps to identify contaminants, pests, and other potential hazards. Proper lighting also helps to prevent cross-contamination between different food products. In addition, lighting helps to identify any issues that may arise during processing, such as product spoilage or contamination, and quickly resolve them to prevent further damage.

- Quality Control: Lighting is also important for quality control in food processing. Proper lighting allows workers to accurately inspect the food products, identify any defects, and take appropriate action to rectify the issue. This helps to maintain the quality of the product and ensure that it meets regulatory standards.

- Productivity: Lighting can also impact the productivity of food processing operations. Poor lighting can lead to mistakes and slow down the processing line, which can result in decreased productivity. On the other hand, good lighting can help to increase productivity by improving visibility and reducing the risk of mistakes.

- Employee Safety: Lighting is also crucial for employee safety in food processing. Poor Food Processing Lighting can lead to accidents and injuries, which can result in downtime and increased costs. Good lighting, on the other hand, can help to create a safer and more comfortable working environment for employees.

Requirements of Food Processing Lighting

Light fixtures for food processing applications must often meet the following requirements:

The luminaires must be able to withstand rigorous cleaning and hose-down protocols, contain no toxic materials, and be highly resistant to corrosion. Contaminants must not enter the processing area from the plenum or the luminaire. The luminaires must have a wet location safety listing, stringent third-party certifications, and perform long-term in cold temperatures within freezers. They must also meet specific illumination requirements.

Best Practices for Food Processing Lighting

- Bright, Even Illumination: Bright, even illumination is essential for food processing, as it helps to identify any contaminants, defects, or other potential hazards. A good lighting system should provide bright and even illumination throughout the processing area.

- Clean and Sanitary: The lighting fixtures and lamps used in food processing should be clean and sanitary to prevent the spread of bacteria and other contaminants. They should also be easily cleaned and maintained to ensure that they remain hygienic.

- Energy Efficient: Food processing is a high-energy use industry, and lighting can contribute significantly to energy costs. Energy-efficient lighting systems can help to reduce energy costs and reduce the environmental impact of food processing operations.

- Durable and Long-lasting: Food processing environments can be harsh, and lighting fixtures and lamps need to be able to withstand these conditions. Durable and long-lasting lighting systems can help to reduce maintenance costs and increase the reliability of the lighting system.

- Adequate Ventilation: Adequate ventilation is also important for food processing lighting, as it helps to prevent heat buildup and improve the performance of the lighting system.

Considerations of total cost

Avoid Early Failures

When selecting Food Processing Lighting luminaires, only choose those with the highest IP-rated enclosures. This will help prevent early failures of LED fixtures. Thermal management is more challenging within sealed fixtures, but is critical to preventing early failure due to heat buildup. Chemical and corrosion resistance is also important for harsh cleaning and hose-down applications.

Reduce Maintenance Costs

The highly-sealed enclosures of these fixtures prevent the labor-intensive cleaning of optic lenses. The chemical and corrosion resistance of these luminaires prevents costly repairs, as does the high impact rating on these luminaires. Choosing hardwired LED sources within the fixture prevents the maintenance costs of repeatedly replacing lamps. Remember that cleaning inside the Food Processing Lighting fixture, repairs and relamping can all halt production & processing operations which can be very costly.

Reduce Energy Costs

The right LED technology Food Processing Lighting can significantly reduce electricity costs when compared to HID luminaires, and fluorescent, even T5HO fixtures.

Use fewer fixtures.

Cold temperatures can drastically reduce the light output of fluorescent lamps, while LED Food Processing Lighting typically maintains equivalent light output even in the freezer. Fluorescent lumens depreciate in cold temperatures, requiring additional fixtures to compensate for the significantly reduced light output. Therefore, choose high performing LED luminaires to reduce the number of fixtures required in these cold spaces.

Food Safety Requirements

When choosing lighting for food processing facilities, it is important to consider the different locations within the building and their lighting requirements. Additionally, there are several regulating agencies that set requirements and standards for food safety.

Food safety agencies, including the U.S. Food and Drug Administration (FDA) and the U.S. Department of Agriculture (USDA), have set standards for food processing facilities that include several regulatory requirements related to Food Processing Lighting:

NSF

NSF International develops public health standards and certification programs for food safety. NSF/ANSI Standard 2 (NSF2) establishes minimum requirements for food equipment, including lighting. The standard defines three types of areas (zones):

Non-Food Zone.

These areas include kitchens, food storage areas, dry process areas, and damp process areas.

Splash Zone.

Including wet or damp process areas, high-pressure purging or decontamination used, and hose wash-down areas.

Food Zone.

Areas where food products are processed, stored or served.

The National Sanitation Foundation (NSF) has created a set of standards designed to prevent food contamination. These requirements include corrosion resistance, cleanability, and the ability of exposed material to withstand normal wear.

USDA, FDA, & IES

The USDA, FDA, and Illumination Engineering Society collaborate to set illumination standards for food processing facilities. The required light levels, expressed in foot-candles and uniformity, vary depending on tasks and food types. Adequate lighting is crucial for maintaining sanitation, as insufficient light can hinder the detection and correction of unsanitary conditions and the avoidance of contaminants. FSIS, part of USDA, requires the highest light levels in inspection areas within food processing facilities, with a requirement of 200 foot-candles of shadow-free light and a color rendering index of at least 85.

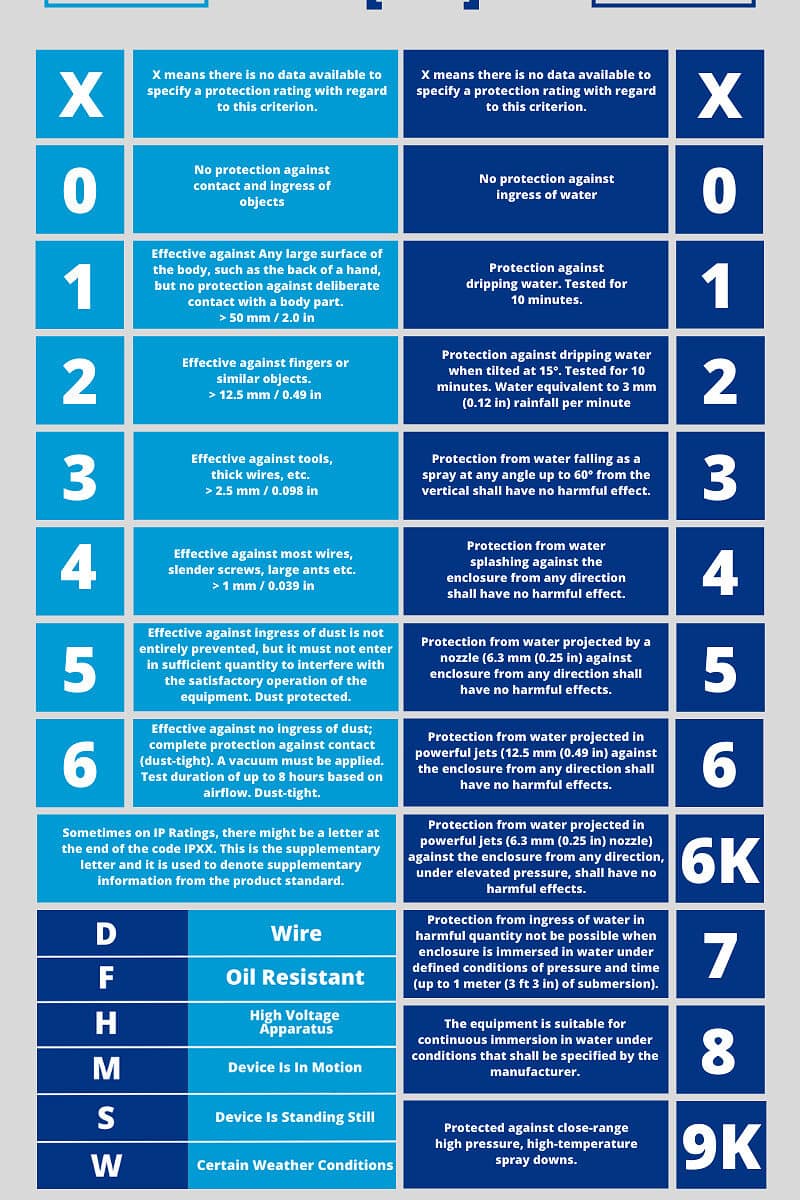

IP69K – IP69K

The IP69K rating offers the highest ingress protection rating available, according to the International Electrotechnical Commission (IEC). The first digit in ’69’ represents the level of protection against solids, dirt, and dust. The highest level of protection for the first digit is a 6, which means no ingress of dust. The second digit is protection from liquid ingress including water. The highest value is a 9 which is protection against steam-jet cleaning. The ‘K’ specifically represents ingress protection against high temperatures and high pressures. Look for IP69K for your most demanding applications.

IP Rating Charts

| First digit | Mechanical Protection | Second digit | Water ingress protection |

|---|---|---|---|

| 0 | No protection | 0 | No protection |

| 1 | Protected against solid objects over 50mm, e.g. accidental touch by hands | 1 | Protected against vertically falling drops of water e.g. condensation |

| 2 | Protected against solid objects over 12mm, e.g. fingers | 2 | Protected against direct sprays of water up to 15 ° from the vertical |

| 3 | Protected against solid objects over 2.5mm, e.g. tools & wires | 3 | Protected against direct sprays of water up to 60 ° from the vertical |

| 4 | Protected against solid objects over 1mm, e.g. wires, nails etc. | 4 | Protected against water splashed from all directions, limited ingress permitted |

| 5 | Protected against dust limited ingress, not harmful deposits | 5 | Protected against low-pressure jets of water from all directions, limited ingress permitted |

| 6 | Totally protected against dust | 6 | Protected against strong jets of water e.g. on the deck of the ship, limited ingress permitted |

| n/a | n/a | 7 | Protected against the effects of temporary immersion between 15cm and 1m. Duration of test 30 minutes |

| n/a | n/a | 8 | Protected against long periods of immersion under pressure |

IK10

The highest rating on the IK scale is IK10. This level of protection is achieved through the use of materials that can withstand a 5 kg (~ 11 lbs) mass dropped from 200 mm (~ 8 inches) above the impacted surface. This represents an impact of 20 joules. Ignoring this information may result in your fixture being compromised with its first impact.

SHATTERPROOF / GLASS-FREE

Broken glass and other luminaire materials can contaminate the food processing facility, so protecting against breakage is critical. NSF establishes requirements to prevent glass breakage, and high impact resistance, like IK10, demonstrates protection against breakage due to impacts.

CHEMICAL RESISTANCE

When looking for a durable solution to harsh environments, consider the construction of the housing. For linear fixtures, look for continuous extrusions without seams and choose co-extruded polymer and aluminum for the best protection. The polymer provides chemical resistance and the aluminum provides mechanical strength and thermal management for the LED components. Make sure the end caps are chemically-welded for a secure bond.

Conclusion:

In conclusion, food processing lighting is essential for ensuring the safety, quality, and productivity of food processing operations. A good lighting system should provide bright and even illumination, be clean and sanitary, energy-efficient, durable and long-lasting, and have adequate ventilation. By following these best practices, food processing operations can ensure that their environment remains safe and hygienic while improving the quality and efficiency of their operations.

Choosing lighting fixtures for food processing facilities can be challenging due to various performance requirements such as:

- ability to withstand cleaning and hose-down

- no toxic materials

- high resistance to corrosion

- prevention of contaminants

- wet location safety listing

- certifications and

- performance in cold temperatures.

To simplify fixture selection, look for luminaires with the highest ratings such as wet location safety listing, NSF certification, IP69K protection, and IK10 impact rating. This will reduce overall cost and simplify selection for various food processing areas. Consider the Food Processing Lighting by Fireflier Lighting as an example.