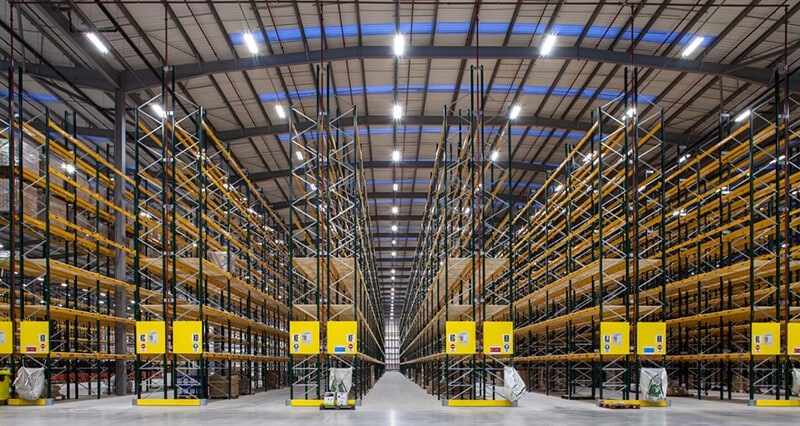

Warehouse operations are complex and demanding, and efficiency is key to success. One often overlooked aspect of warehouse efficiency is lighting. Proper lighting not only creates a safe working environment, but it also improves productivity and reduces energy costs. In this article, we will discuss how next-generation industrial lighting technology can help warehouse warriors boost efficiency.

The Role of Lighting in Warehouses

Proper lighting in warehouses is essential for several reasons. Firstly, it creates a safe working environment by ensuring that workers can see clearly and avoid accidents. Poor lighting can lead to slips, trips, and falls, and can also make it difficult for workers to operate machinery or navigate the warehouse.

Secondly, lighting affects productivity. Studies have shown that adequate lighting can improve worker performance and reduce errors. In contrast, poor lighting can lead to eye strain, headaches, and fatigue, which can reduce productivity and increase the risk of mistakes.

Finally, lighting can impact energy costs. Warehouses often have high ceilings and large areas that require lighting, which can lead to high energy bills. By using energy-efficient lighting technology, warehouses can reduce their energy consumption and save money on their bills.

Next-Generation Industrial Lighting Technology

Next-generation industrial lighting technology is a game-changer for warehouses. These advanced lighting systems use LED technology and smart controls to create a more efficient and sustainable lighting solution.

LED lighting is far more energy-efficient than traditional lighting technologies. LEDs use up to 80% less energy than incandescent bulbs and last up to 25 times longer. This means that warehouses can reduce their energy bills and maintenance costs by switching to LED lighting.

Smart controls are another important feature of next-generation industrial lighting technology. These controls allow warehouses to adjust their lighting levels based on occupancy, daylight, and other factors. For example, lights can be turned off in areas that are not in use, or dimmed when there is sufficient natural light. This not only saves energy, but it also reduces the wear and tear on the lighting system, leading to longer lifetimes and lower maintenance costs.

Another important feature of next-generation industrial lighting technology is the ability to integrate with other systems. For example, lighting systems can be integrated with sensors that monitor temperature, humidity, and other environmental factors. This can help warehouses to optimize their operations and improve efficiency.

Benefits of Next-Generation Industrial Lighting Technology

By using next-generation industrial lighting technology, warehouses can enjoy several benefits, including:

- Improved safety: LED lighting provides bright and uniform light, making it easier for workers to see and navigate the warehouse. This reduces the risk of accidents and injuries.

- Increased productivity: Adequate lighting can improve worker performance and reduce errors, leading to increased productivity.

- Energy savings: LED lighting is more energy-efficient than traditional lighting technologies, leading to lower energy bills and reduced carbon emissions.

- Lower maintenance costs: LED lighting lasts longer than traditional lighting technologies, reducing maintenance costs.

- Smart controls: Smart controls allow warehouses to adjust their lighting levels based on occupancy, daylight, and other factors, leading to additional energy savings.

Case Study: Amazon

Amazon is one of the largest and most successful retailers in the world, with a massive network of warehouses and fulfillment centers. To improve efficiency and sustainability, Amazon has invested heavily in next-generation industrial lighting technology.

In 2017, Amazon announced that it would be installing LED lighting and smart controls in its fulfillment centers. The company estimated that this move would save 20% in energy costs, or roughly $400 million over the next 15 years. The LED lighting is also expected to last 20 years, compared to just 5 years for traditional lighting technologies.

Amazon has also integrated its lighting systems with other technologies, such as sensors and automation systems. This has allowed the company to optimize its operations and reduce its environmental impact. For example, sensors in the lighting system can detect when areas are not in use and automatically turn off the lights, saving energy and reducing wear and tear on the lighting system.

Conclusion

In conclusion, next-generation industrial lighting technology is a valuable tool for warehouse warriors looking to boost efficiency. By using LED lighting and smart controls, warehouses can improve safety, increase productivity, save energy, and reduce maintenance costs. The integration of lighting systems with other technologies can further optimize operations and reduce environmental impact. As demonstrated by Amazon, investing in next-generation industrial lighting technology can have significant benefits for businesses and the planet.